Food processing

Soluciones

Las materias primas frescas que no van directamente al mercado de consumidores generan sobras de calidad alimentaria que pueden reducirse a productos para piensos. Esto representa un menor rendimiento y una pérdida en cuanto a la producción. Haarslev ayuda a transformar las sobras en una fuente de ingresos valiosa al convertirla en productos en polvo con alto valor proteico para el mercado de los alimentos o la carne o en un ingrediente de alta calidad para la industria de los alimentos para mascotas.

soluciones

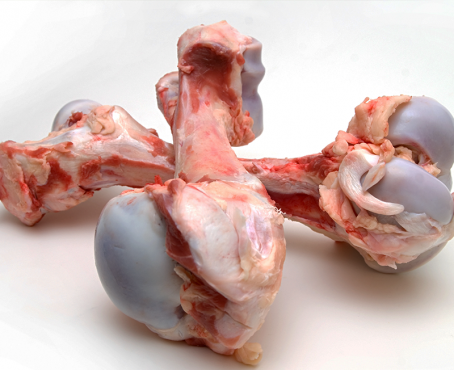

Suitable raw materials are: fresh poultry meat and bone leftovers, mechanically deboned products, animal bones, connective and fat trimmings and seafood by-products.

Aves

Procesamiento

From the poultry application fresh meat cuts, trimming or carcass can be collected and chilled before they are processed into flavour soup extract or broth product. The final product can be concentrated liquid and can be sold in chilled form or dried into a powder with outstanding taste, nutrition and 100% solubility.

Available process solutions-

Digestion BONE EXTRACT Processing Line

A continuous digestion process engineered system for meat and bone material to customer specification from low to medium capacity.

-

BONE SOUP (BROTH ) Processing Line

A continuous pressure cooking process engineered system for meat and bone material to customer specification from low to medium capacity.

BONE

PROCESAMIENTO

From the deboning rooms in a slaughtering or meat producer's plant, fresh meat cuts, trimming or bone leftovers are collected and turned into a food ingredient or a meat substitute final product. The final liquid product is concentrated and can be sold in chilled form or dried into a powder with good functionalities and nutrition value.

AVAILABLE PROCESS SOLUTIONS-

Digestion BONE EXTRACT Processing Line

A continuous digestion process engineered system for meat and bone material to customer specification from low to medium capacity.

-

BONE SOUP Cooking Processing Line

A continuous pressure cooking process engineered system for meat and bone material to customer specification from low to medium capacity.

FAT AND PROTEIN

PROCESAMIENTO

From the deboning rooms in a slaughtering or meat producer’s plant, fresh trimming cuts and fat leftovers are collected and turn into a food grade edible lard or tallow and an edible protein meat as substitute final product with enhanced functionalities.

AVAILABLE PROCESS SOLUTIONS-

Fat and Melting Processing Line

A continuous engineered system to process fatty cut off and trimming material into food grade fat and functional edible protein to customer specification from low to high capacity.

FISH OIL

PROCESAMIENTO

From the seafood application fresh head frame and fish skin and partly organs can be pumped to a process line to make high grade fish oil for food or nutraceutical purpose. Extreme fresh raw material like liver can be processed in a few minutes, which offers a high-grade fish oil product like COD liver or other fish enriched with EPA and DHE content.

AVAILABLE PROCESS SOLUTIONS-

Ultra Short Processing Line

A continuous processing modulated to make high-grade fish oil.

Cuidar

el futuro

El departamento de Servicios Técnicos de Haarslev se asegura de que su negocio siga funcionando

Tener tiempo de inactividad es lo peor para todas las compañías. Hay que evitarlo a toda costa. Nuestros sistemas han sido diseñados para garantizar el máximo tiempo de actividad.

El Departamento de Servicios Técnicos de Haarslev le ayuda a que su planta siga funcionando de manera confiable, eficiente y rentable cada día del año.

Contamos con expertos altamente capacitados para darle el mejor asesoramiento cuando se trata de dominar sus procesos, y al implementar los procedimientos correctos para mantenimiento y stock de repuestos podrá:

- garantizar su productividad

- obtener un mayor rendimiento por producto

- lograr un menor costo total de la propiedad (TCO)